Overview

Impro is among the global Top 5 sand casting companies for complex high-performance iron sand castings, according to Roland Berger’s 2019 Report.

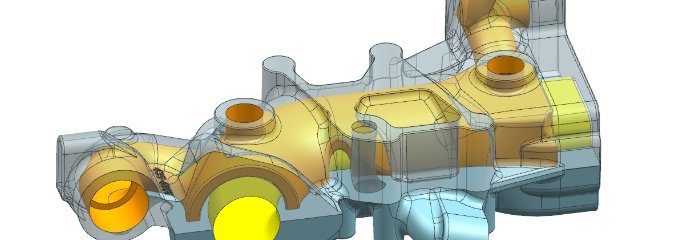

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification. The sand shell is subsequently removed after the metal components cooled and formed.

LEARN MORE

Impro is a leading global manufacturer of complex and high value-added sand castings using resin sand casting process. This video is to highlight the key steps of a typical multi-cored and complex resin sand casting part.

LEARN MORE

Impro offers one-stop solutions for all your sand casting needs. We provide a full suite of state-of-the-art process technology and equipment throughout our multiple facilities.

LEARN MORE

Impro can meet material specifications according to a variety of industry standards and custom specifications. Our material capabilities include ductile iron, gray iron, and compacted graphite iron (CGI).

LEARN MORE

We have both green sand and resin sand casting production lines using fully automatic molding and floor molding technologies. We produce highly complex and high value-added sand casting products for diverse end markets.

LEARN MORE

Impro engineering team is very experienced in developing complex sand castings using 3D printing technologies. 3D printing technology offers a myriad of benefits.

LEARN MORE

Impro manufactures sand castings for diverse end markets. Typical products include engine blocks, cylinder heads, cylinder pistons, frames, brackets, manifolds for high-horsepower engines, impellers, housings, gearbox parts of transmission systems for construction, and agriculture equipment.

LEARN MORE