Process Introduction

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification. The sand shell is subsequently removed after the metal components cooled and formed. Certain sand casting components require a secondary machining process after casting. Sand casting can process a wide range of metals and alloys, including iron, special alloy steel, titanium alloy, and others. Sand casting is a cost-effective and efficient technology, which is generally flexible with regards to size and change of geometry design. Secondary machining is usually needed to improve product accuracy.

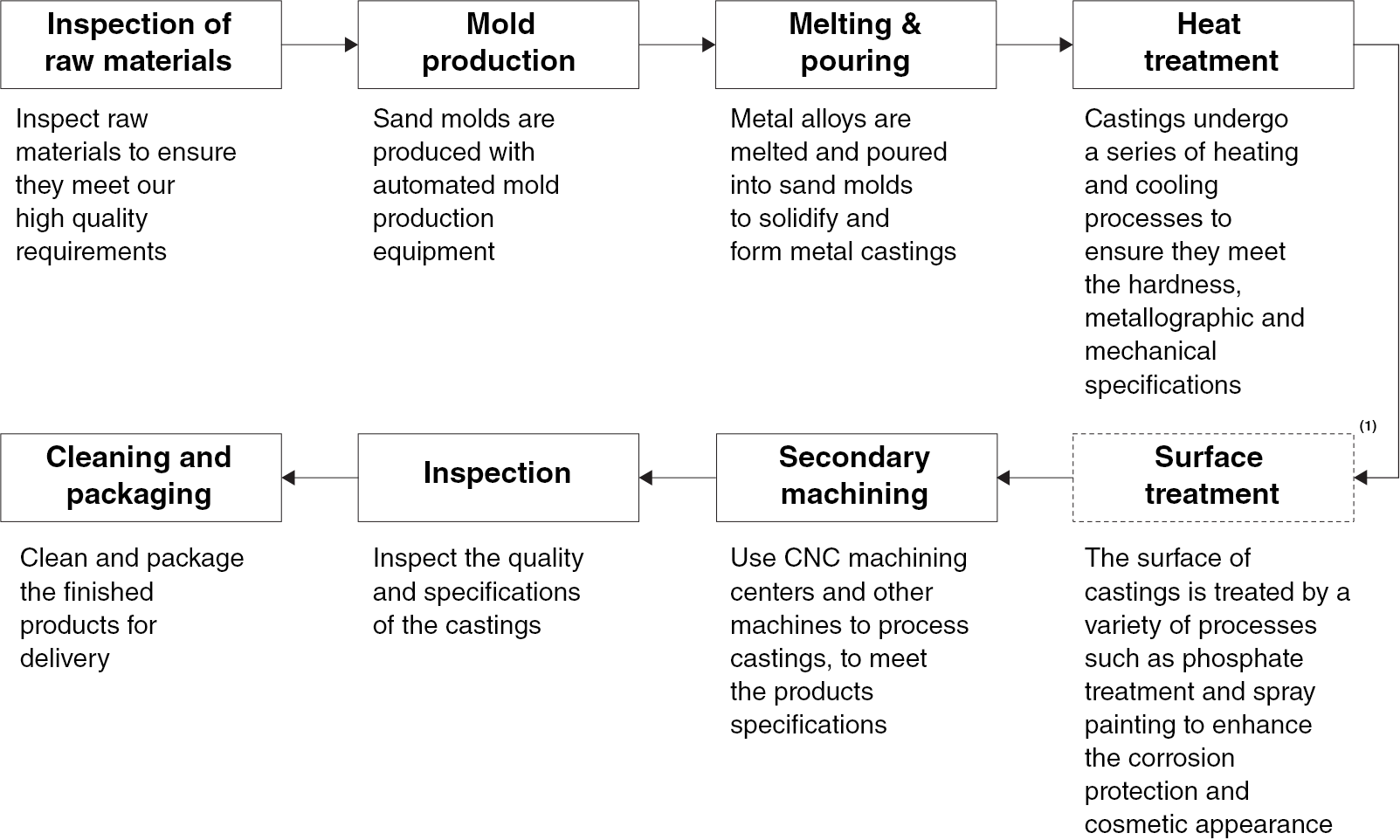

Flowchart Illustrating Key Steps of Sand Casting Process

Note: (1) Some (and not all) sand casting components require surface treatment.

For a typical sand casting order, the Impro sand casting process generally takes approximately three to five weeks to complete.