Capabilities

| Region | Process | Weight (kg) | Process Parameter | Suitability |

|---|---|---|---|---|

| Mexico | Sinto FBO Automatic Green Sand Molding Line | 0.5-40 | Flask size: 610×508×250/250 mm 100 molds per hour |

Elbow, cover, bracket, manifold, bearing housing, transmission parts, impeller, turbine casing, and more |

| KW Automatic Green Sand Molding Line | 30-400 | Flask size: 1350×1000×450/450 ~250/250mm 100 molds per hour |

Housing, case, cover, wheel, carrier, bracket, flywheel, flywheel housing, gear housing, cylinder block, cylinder head, oil pan, shaft, and more | |

| China | Sinto FBO Automatic Green Sand Molding Line | 0.5-40 | Flask size: 610×508×250/250 mm 80 molds per hour |

Elbow, cover, bracket, manifold, bearing housing, transmission parts, impeller, turbine casing, and more |

| IMF Automatic Resin Sand Molding Line |

20~220 | Flask size: 1200x800x500/500mm; 15 molds/hour |

Elbow, bracket, manifold, bearing housing, transmission parts, and more | |

| IMF Automatic Resin Sand Molding Line |

30-600 | Flask size: 1600×1200×600/600mm; 10 molds per hour |

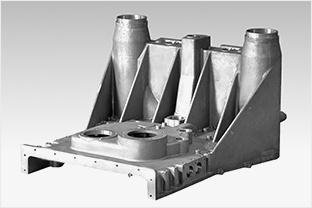

Housing, casing, bracket, pipe, manifold, carrier, shaft, transmission parts, cylinder head, cylinder block, and more | |

| Resin Sand Molding, Pit Pouring |

10-8000 | Flask size: 4200×3200×1000/1000 mm max 500×400×100 /100mm min |

All cast iron parts, large-sized cylinder block, gear housing, flywheel, flywheel housing, oil pan, and more |

Detailed product description for resin sand castings:

- Cylinder Block: All types of inline and “V” type up to 3,200 kg per piece, raw or machined.

- Cylinder Heads: From 40 kg per piece to 300 kg per piece, multi-cored, raw or machined.

- Hydraulic valve bodies

- Gear Box parts

- Other complex cored castings

- Machine molding, manual molding

Medium to High Volume Green Sand Casting

Our machine molded castings department manufactures castings with a weight from 0.5 kg to 20 kg

Detailed product description for green sand castings:

- Hydraulic valve bodies

- Gear Box parts

- Planet carrier

- Steering knuckles

- Other complex cored castings

- Machine molding, manual molding

Our services include:

- Material advisory service and development

- Technical advice on design and casting

- 3-D CAD drawings

- Simulations

- Cavity fill, solidification, tension and distortion

- Component machining

- Assembly

- Testing and qualification