Process Introduction

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps. Heat treatment, a special process, such as carburizing, quenching, tempering, may be deployed during precision machining for special needs. Precision machining often requires the programing of computer numerical controls, or CNC, which allows for converting special designs into exact shapes through multiple dimensions. Precision machining components are commonly supplied to OEM customers and system integrators. Finished parts are used in diverse end-markets.

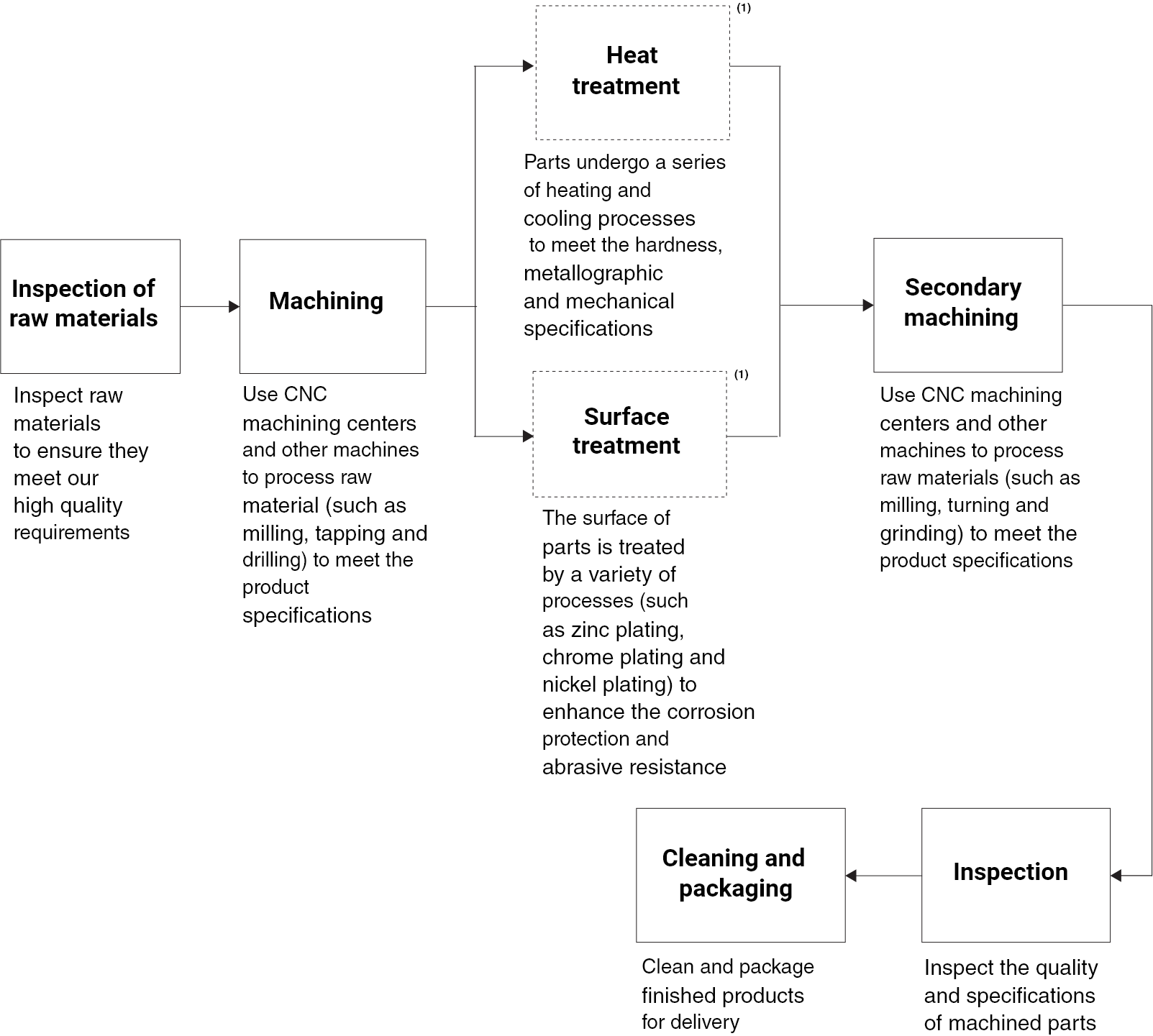

Flowchart Illustrating Key Steps of Precision Machining Process

Note: (1) Some (and not all) precision-machined components require heat treatment and/or surface treatment.