Equipment

Impro uses high-quality processing equipment to satisfy the needs of customers around the world. Catering to sectors ranging from the medical, automotive, hydraulic, and oil and gas industries, Impro provides a diverse array of precision CNC machining solutions to our customers.

State-of-the-Art Processes

We uphold the highest standards for our technology and equipment. Our turning and milling processes adhere to strict positioning and machine accuracies. For grinding processes, we have cylindrical grinding machines, and centerless grinding. We also offer a wide variety of heat treatments including high-frequency-line induction quenching, freezing techniques, vacuum lines, nitriding furnaces, and multipurpose heat treatment.

A full list of our processes and equipment is below:

Turning

CNC Turning Machines

- Process range: 0–Ø550 ×1,079 mm

- Machine accuracy: ±0.005 mm

- Quantity: 300+

- Brand: Hardinge, Doosan, and Takisawa

CNC Hard Turning Machines

- Process range: Ø3–Ø285×300 mm

- Machine accuracy: ±0.01 mm

- Capacity: Hard turning equipment and granite filling lathe bed turning instead of grinding

- Surface roughness: Ra 0.2 μm

- Roundness: 0.4 μm

- Continuous turning accuracy: 5 μm

- Brand: Hardinge, DMG

Turning Centers

- Process range: 0–Ø32 × 320 mm

- Machine accuracy: ±0.01 mm

- Quantity: 60

- Brand: Star, Citizen, Tsugami, Tornos and Traub

Milling

Vertical/Horizontal Milling Center

- Process range: 1,035 × 508 × 635 mm

- Positioning accuracy: ±0.01 mm

- Spindle speed: 12,000 rpm

- Quantity: 300+

- Brand: DMG, Haas, Hardinge and Doosan

Deep-Hole Drilling

- Process range: Φ0.8–12 × 400 mm

- Spindle quantity: 4

- Hole tolerance: 15 μm

- Surface roughness: Ra 0.8 μm

- Brand: TBT

Turning/Milling

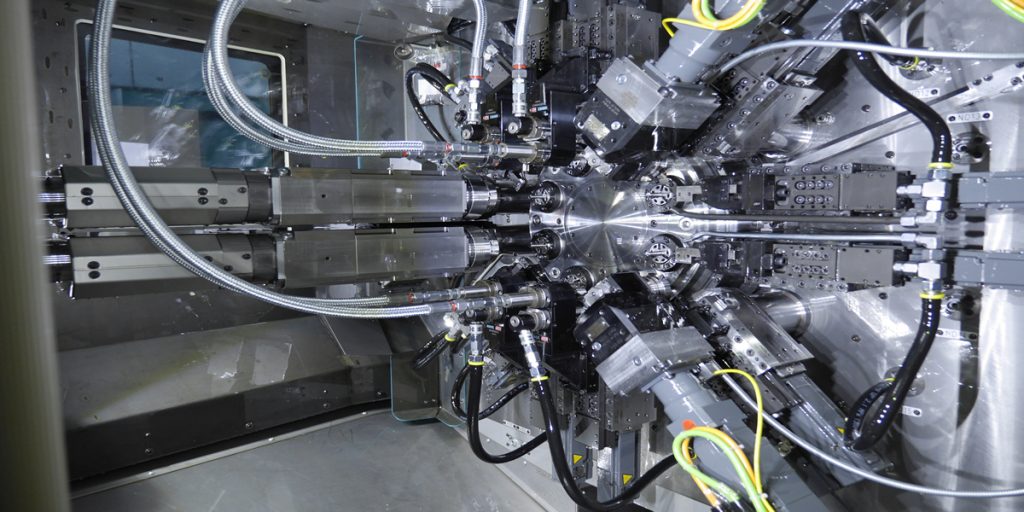

Multi-Spindle Machines

- Type: MS 32C

- Max. bar diameter: Φ 32 mm

- Max. turning length: 120 mm

- Spindle quantity: 6

- Spindle speed: 10,000 rpm

- Capacity: 1.5 M/min

- Quantity: 50+

- Brand: INDEX

Grinding

Centerless Grinding

- Process range : 0–Ø50 × 405 mm

- Roundness: 0.5 μm

- Flatness : 1.0 μm

- Brand: Micron, Mikrosa and Tschudin

Cylindrical Grinding Machine

- Process range : 0–Ø350 × 1,000 mm

- Roundness: 0.4 μm

- Flatness: 1.0 μm

- Brand: Kellenberger, Cometa, and Studer

Honing Machine

- Process range : Ø0.7–Ø70 × 120 mm

- O: 0.002 mm (blind hole)

- Brand: Pemamo, Nissin and Gehring

Deburring

- Abrasive flow deburring

- Thermal energy deburring

- Electrochemical deburring

- Special deburring

Heat Treatment

Multipurpose Heat Treatment Line

- Effective working region: 1,000 × 700 × 650 mm

- Highest operating temperature: 950°C

- Temperature uniformity: ±6℃

- Quenching medium: Oil

- Functions:

- Carburizing and quenching for carbon steel and alloy steel

- Carbonitriding

- Hardening and tempering for carbon Steel

- Brand: Aichelin

Vacuum Heat Treatment Line

- Effective working region: 900 × 600 × 450 mm

- Highest operating temperature: 1,320℃

- Temperature uniformity: ±5℃

- Quenching medium: Oil

- Function: Bright quenching for stainless steel, ball bearing steel, and alloy steel

Freezer

- Effective working region: 1,150 × 750 × 700 mm

- Lowest operating temperature: -196 ℃

- Function: Remove retained austenite and stabilize dimensions

Nitriding Furnace

- Effective working region: Φ650 × 1,200 mm

- Highest operating temperature: 650℃

- Temperature uniformity: ±6℃

- Functions: Gas nitriding and gas nitrocarburizing

- Brand: Aichelin

Induction Quenching with High Frequency Line

- Maximum part size: Φ 400 × 1,000 mm

- Power: 10–100 KW

- Frequency: 150 KHz

- Depth 0.8–4.0mm