Process Introduction

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency. Impro provides surface treatment services mainly through electroplating and, to a small extent, non-electrolytic coating.

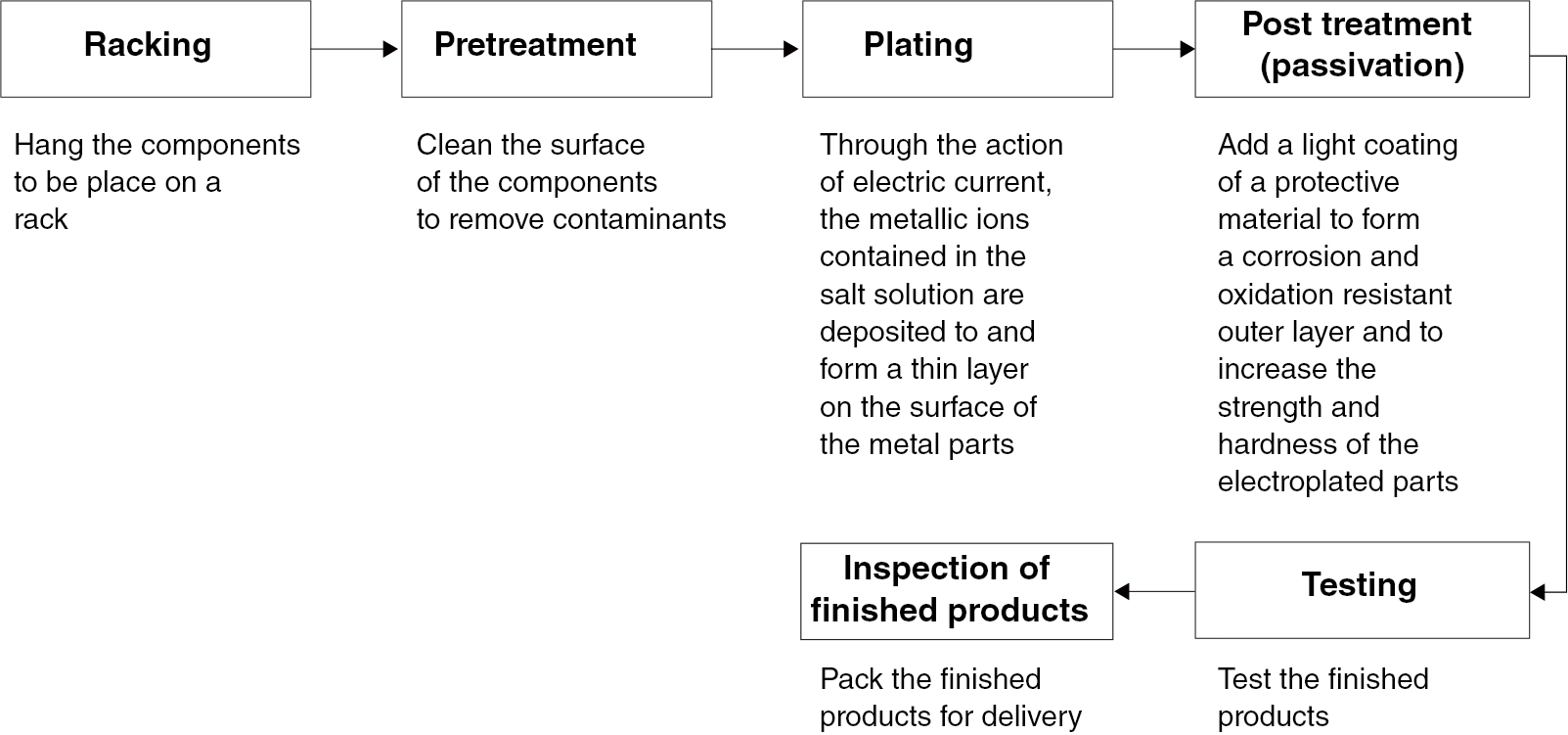

Electroplating is a process used to change a metal part’s surface properties by adding a metal coating onto its surface through electric currents. The metal part to be coated is first immersed in a salt solution that contains the metal to be deposited. The metallic ions of the electrolyte solution carry a positive charge and are attracted to the metal part, which carries a negative charge.

Impro electroplating services can be broadly divided into functional electroplating processes that improve the conductivity, wear-resistance, and corrosion resistance of the components and decorative electroplating, which is performed mainly for decorative purposes. Impro also provides non-electrolytic coating, which applies corrosion-resistant materials and other functional materials to the objects’ surface to improve corrosion resistance, wear-resistance, and decorative function.