Extensive Manufacturing Capabilities

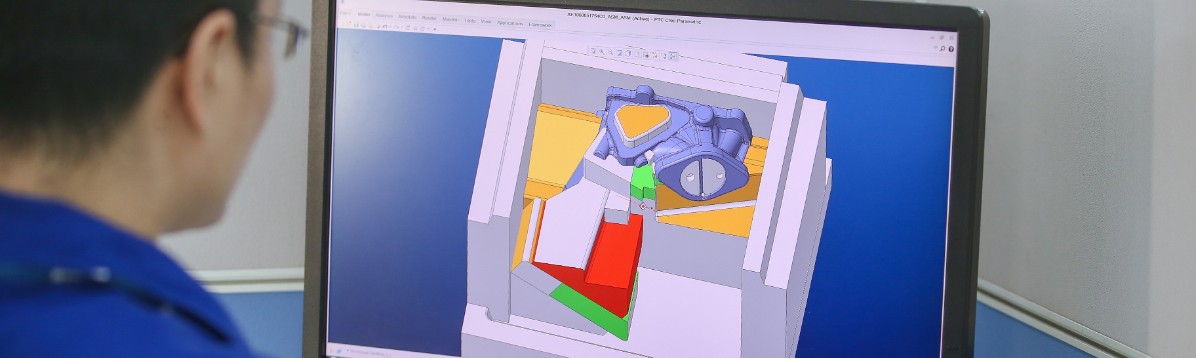

Impro can undertake both investment casting and sand casting, in a wide range of materials. Our expertise extends to tooling development and we understand the complex interactions between process capabilities and product design. Our specialists can advise on the most appropriate process for your part, and can help optimize the design to save money and improve quality.

Impro has made substantial investments in casting and precision machining capabilities. These include:

- Automatic wax pattern injection, robotic shell making lines, air and vacuum melting and pouring

- Automatic green and resin sand casting lines

- 4-axle, 5-axle machining centers

- CNC milling and turning machines capable of high accuracy and repeatability

- ID, OD and centerless grinding

- Honing

Many precision parts require heat treatment before or after machining. This could be for stress relief or to modify properties like hardness and toughness. We can perform a range of heat treatment processes and also have cryogenic capabilities for specializedhardening and toughening requirements.