Investment Casting Waxes: Different Wax Types

Manufacturers use a range of techniques to create complex parts and components. One of the oldest methods that is still used today is investment casting. This process involves creating the item out of wax and then building a ceramic shell around it. Once the shell is complete, the wax is melted out (called dewaxing) before the molten metal is poured into the ceramic shell. Once the metal solidifies, the ceramic shell is removed as the part is now created.

There are numerous waxes that can be selected. The type of wax used will be based on several factors including flow properties, whether the wax will be reclaimed and recycled, dimensional consistency, surface finish and the requirements of the application. Several waxes that you will often hear about are filled pattern wax, non-filled pattern wax, runner wax, water-soluble wax and sticky wax.

Filled Pattern Waxes

Filled pattern waxes are a type of investment casting wax that has fillers added. These fillers can provide certain properties to the casting to ensure strength, dimensional stability, lower thermal expansion and minimal shrinkage. The types of fillers that are found in filled pattern waxes will vary based on the supplier, yet some common fillers may include bisphenol-A (BPA), organic fillers, terephthalic acid, and cross-linked polystyrene.

Both small and large wax pattern productions can use filled pattern waxes. Two major advantages to these waxes are that they have low thermal expansion and minimal shrinkage. They don’t require wax chills to be placed into the cavity of the patterns to prevent shrinkage as the wax solidifies.

This wax is often used when you are looking for more dimensional control of the created part or component and when using a wide range of injection temperatures. Due to the filler added, some wax may remain in the ceramic shell after the dewaxing process as it takes longer for the wax to be burnt out. Filler pattern waxes can be difficult to reclaim and recycle depending on the density of the filler material.

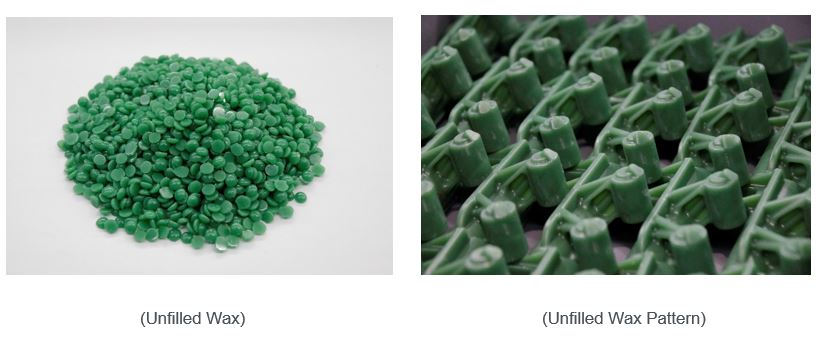

Non-filled Pattern Waxes

Non-filled, or unfilled, pattern wax blends contain less filler materials. This type of wax offers consistent mechanical performance and thermal performance. They are typically used for small and medium wax patterns when there are complex geometries and very defined patterns. Non-filled waxes have exceptional flow properties.

A main advantage to non-filled waxes is that they provide a high surface quality. So the ceramic mold will have fewer cracks and defects. It also completely dewaxes from the ceramic shell as it can be reclaimed and recycled.

Care must be taken when using non-filled waxes in investment casting processes. Due to a slower solidification, the surface of the pattern can sink. There may also be unwanted shrinkage along cross sections of the pattern depending on the wax temperature. Depending on the part configuration, the use of wax chills may be necessary with non-filled pattern waxes to avoid material shrinkage.

Runner Waxes

Runner wax blends are used by investment casting companies when desiring exceptional mechanical strength and lower viscosity. This type of wax has a lower melting point than pattern waxes. So it will drain completely out of the ceramic mold during the dewaxing process without the need to use higher temperatures.

Advantages to runner wax is that it has good soldering strength and minimum thermal expansion. The workers can handle the wax without worrying about the part breaking in the ceramic mold. The wax pattern will need to be immersed in water and stored there until it completely solidifies.

Water-Soluble Waxes

Some parts and components will require complex and intricate internal designs. So the wax pattern must have intricate cores placed inside. To create these cores, a water-soluble wax is used. Once the core is completed, it is placed into the wax pattern die and then the pattern wax is injected into the die. When the wax pattern is cooled, the water-soluble cores are dissolved inside by placing the pattern into a water and acid bath.

Sticky Waxes

Sticky waxes are commonly used during mounting and finishing processes. These waxes help bond different pattern waxes together or when constructing a sprue assembly. The wax helps to create a strong adhesion with the parts so that they will stand up to being handled by workers when creating the ceramic shell.

Impro’s Investment Casting Services

At Impro, we offer investment casting for a wide range of applications including automotive, medical, aerospace, and industrial equipment. When you are looking for an economical manufacturing process that is trusted, reliable and repeatable, investment casting can provide superior results. Contact us today for more information.