Process Introduction

Investment casting is one of the most sophisticated casting processes, enabling intricate shapes while still maintaining high dimensional accuracy and high surface quality. Investment casting can be used to cast almost any metal satisfying application requirements in diverse end-markets.

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed. Molten metal is then poured into the ceramic mold to form a casting component. The ceramic mold is subsequently removed, and the casting components are created. Some investment castings require a secondary machining process after casting. Investment casting is usually used to produce parts in complex shapes with high precision and surface requirement.

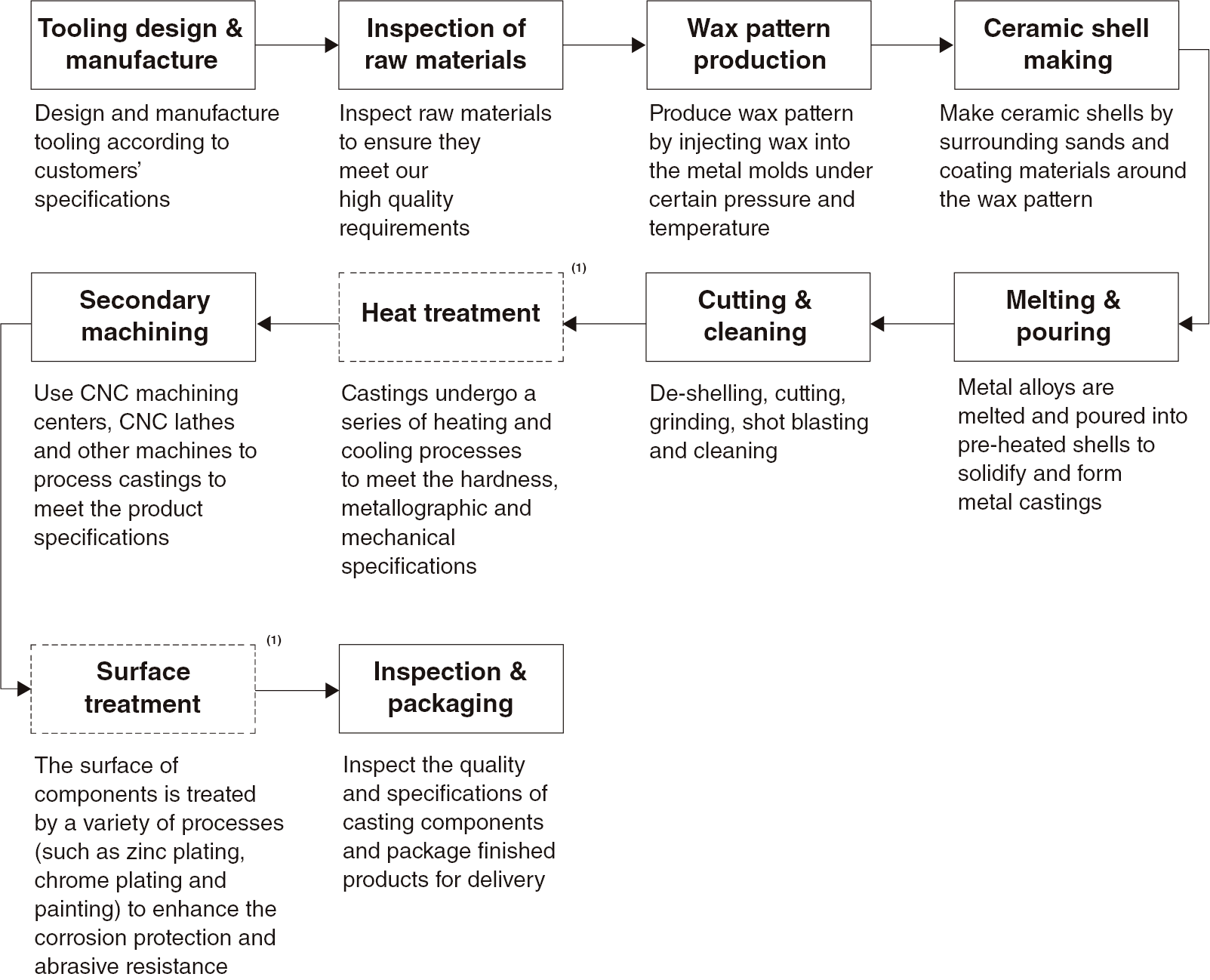

Flowchart Illustrating Key Steps of Investment Casting Process

Note: (1) Some (and not all) investment casting components require heat treatment and/or surface treatment.